In the past, when we talked about industrial factory waste, the word “waste” was often viewed as something that must be eliminated as quickly as possible. Whether it was wastewater, sludge, or residual raw materials from the production process, the result was that countless industries had to use enormous resources and energy for their disposal—through incineration, landfilling, or various forms of treatment—ultimately becoming a burden transferred back to the environment in another way.

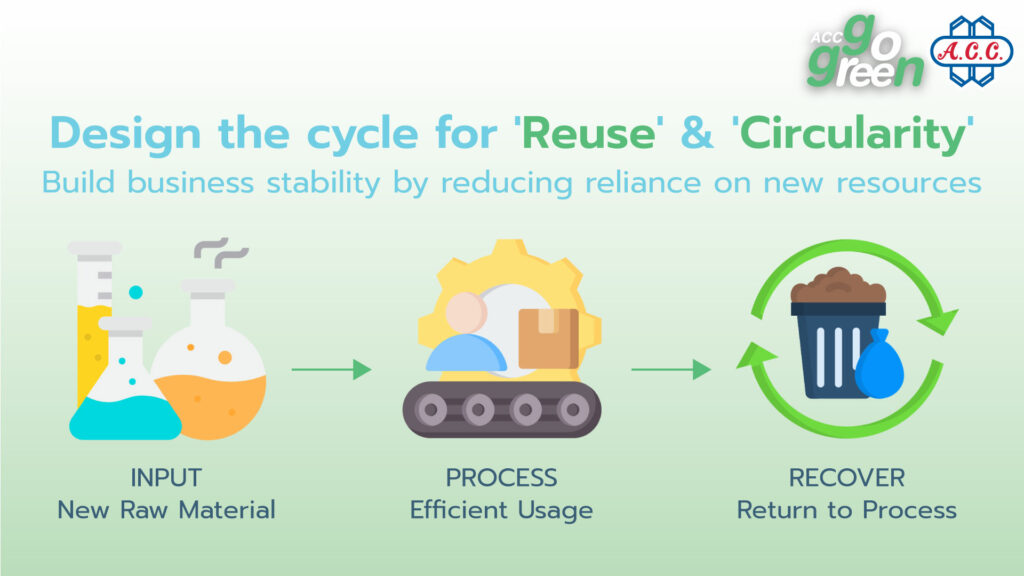

But as natural resources dwindle and the pressure for sustainability continuously escalates, industries worldwide have begun to ask themselves a new question: “How can we design our production processes to become more fully circular?”

This question is the starting point for a major paradigm shift: from “waste that must be eliminated” to “resources that can still be utilized.” Because in reality, certain types of waste have not lost their value; rather, they conceal the potential for reuse, whether in the original process or in other industries. This is the creation of a new equation that proves that responsibility to the planet can truly advance alongside the creation of business stability.

Understanding Circular Chemical

Circular Chemical does not just mean recycling plastic; it is about designing the life cycle of chemicals and materials from the beginning to the end, ensuring that they are reused, recycled, or recovered as raw materials to feed into other production processes as much as possible. To gain a clearer picture, let’s look at the core components of this concept in practice:

-

Waste-as-Secondary-Resource

In many production processes, residual chemicals or leftover residues from wastewater treatment can be extracted and processed into starting raw materials for production in other industries. A clear example is the management of Sludge from wastewater treatment systems that use Coagulants. In the past, this sludge was sent for disposal, representing a cost. However, under the Circular Chemical concept, if that sludge is of high purity (such as sludge from the food industry), it can be processed through dewatering and conditioning to be used as a Soil Conditioner or as a material for construction in some capacity, thereby turning a disposal liability into a valuable product.

-

Durability and Reusability

This involves selecting high-quality chemicals that are resistant to degradation and can be reused multiple times in the same process without compromising performance. An example is the use of Solvents that can be purified through distillation and returned to the original production cycle.

-

Minimizing Hazardous Input

In line with the principles of the green industry, the Circular Chemical concept advocates for the selection of chemicals with low toxicity or those that are naturally biodegradable, ensuring that the resulting End-of-Life Waste poses the least risk to the environment, even if complete recovery is not feasible.

From Liability to Stability

From Liability to Stability

Implementing the Circular Chemical concept in the industrial sector is not merely about “doing good”; it is a “business strategy” that creates sustainable competitive advantages across multiple dimensions:

-

Resource Efficiency and Cost Reduction

When certain waste products become raw materials, the reliance on external virgin resources decreases. This provides organizations with greater security in raw material supply and better control over long-term production costs. Furthermore, it significantly reduces the expenses associated with transporting and disposing of waste.

-

Risk Mitigation

Investing in circular technologies reduces the risks arising from the constantly tightening Environmental Regulations. It also lowers the risks associated with corporate image and conflicts with communities due to inadequate waste management.

-

Market Access and Business Opportunities (ESG)

Today’s investors and consumers pay serious attention to ESG indicators. Businesses that demonstrate a firm commitment to efficient waste management based on Circular Chemical principles receive higher ESG scores. This can increase opportunities for accessing funding and gaining the trust of business partners who value a Green Supply Chain.

-

Innovation Driven by Circularity

When organizations view waste as an “opportunity,” it sparks research and development of new technologies to extract value from these wastes. This, in turn, leads to the creation of new products or the improvement of production processes for higher overall efficiency.

Key Components Driving Circular Chemical

The Circular Chemical concept cannot be realized without the support of modern technology, which plays a vital role in completing the production loop, as follows:

-

Advanced Treatment Technology for Water Reclamation

Conscious factories invest in advanced wastewater treatment systems, such as Membrane Filtration or Advanced Oxidation Processes (AOPs), to ensure that the effluent water from production is clean enough to be reused as cooling water or in processes that do not require high purity (Water Reuse).

-

Extraction and Recovery of Valuable Metals (Metal Recovery)

In the electronics or metal plating industries, wastewater often contains heavy or valuable metals. Modern technologies, such as Electrocoagulation or the use of Ion Exchange Resins, can help recover these metals for reuse, rather than allowing them to be discharged.

-

Tailor-Made Chemicals

Developing chemical solutions that not only work efficiently but are also designed to be easily separated after use. This allows the primary chemicals to be recovered and reintroduced into the cycle quickly.

Conclusion

Conclusion

The “Circular Chemical” concept has completely redefined “waste,” transforming it from a liability into an opportunity. It proves that sustainable production is not a difficult endeavor, provided that organizations are ready to invest in innovation and shift their perspective. A business that understands and applies this principle is a business that is building long-term resource stability for itself, while simultaneously contributing to a cleaner and more livable world for everyone. The commitment to “leave nothing behind” is therefore the new value the world is looking for from your business.