Global warming is an environmental issue that affects lives and economies around the world. One of the main causes of this phenomenon is the emission of greenhouse gases from human activities, especially from the industrial sector. This article explores the role of industrial factories in global warming, the resulting impacts, and management approaches to build a sustainable future.

The Role of Industrial Factories in Greenhouse Gas Emissions

Industrial factories are a major source of greenhouse gas emissions because the production processes often rely on energy generated from burning fossil fuels, which release carbon dioxide (CO₂) and other gases that contribute to the intensification of the greenhouse effect. Additionally, certain production processes, such as cement and steel manufacturing, directly emit greenhouse gases through chemical reactions during the production process.

The Impact of Pollution from Industrial Factories on Air Quality and Health

Air pollution from industrial factories not only contributes to global warming but also affects air quality and public health. Pollutants such as sulfur dioxide (SO₂) and nitrogen oxides (NOx) emitted from production processes can lead to acid rain and respiratory problems in humans. Moreover, fine particulate matter (PM2.5) generated from fuel combustion can penetrate the respiratory system and cause various diseases.

Green Supply Chains and ESG Standards in the Industrial Sector

Green Supply Chains and ESG Standards in the Industrial Sector

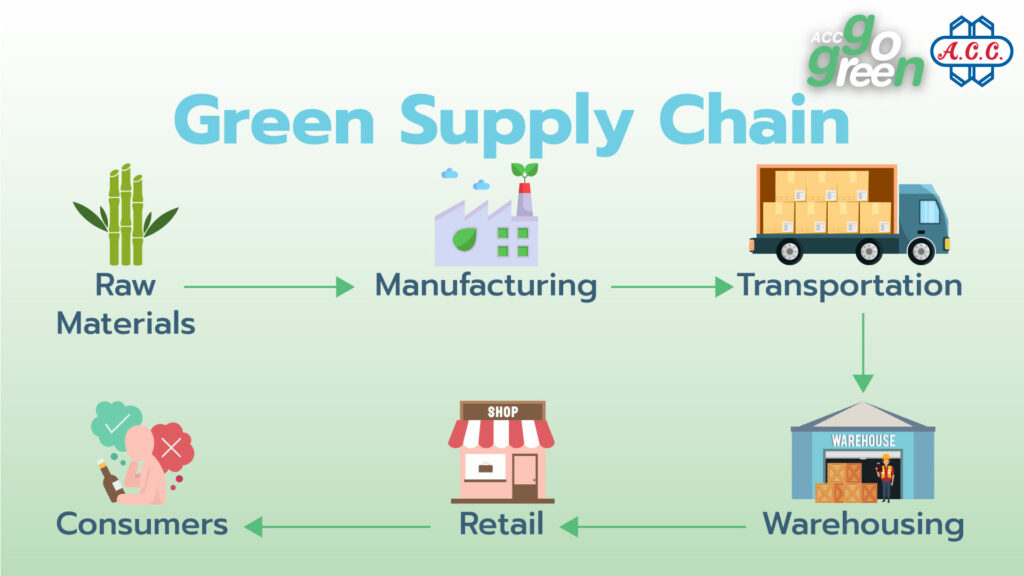

In recent years, “sustainability” has become one of the core requirements for businesses worldwide, particularly for the industrial sector, which faces pressure from consumers, investors and government authorities. The transformation is not limited to the factories themselves but extends across the entire supply chain, also known as the “Green Supply Chain” prompting manufacturers to consider sustainability from raw material sourcing to end consumers.

Furthermore, the ESG approach (Environmental – Social – Governance) has become an important standard used to evaluate the credibility and potential of businesses. ESG encourages the industrial sector to adjust its management practices, such as reducing carbon footprints, caring for factory workers, complying with environmental laws, and disclosing information transparently. If implemented earnestly, it will build long-term trust from investors.

Carbon Footprint for Organization (CFO) Assessment and Reporting

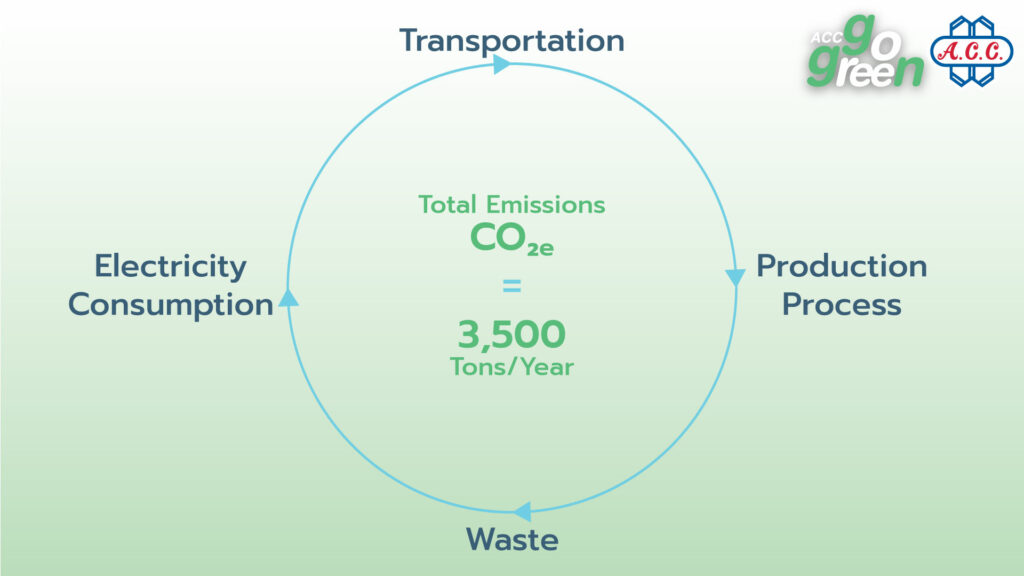

The importance of carbon footprint assessment lies in the fact that sustainable management in the industrial sector requires systematic measurement tools to evaluate and control greenhouse gas emissions. One popular method is calculating the Carbon Footprint for Organization (CFO), which measures the total amount of greenhouse gas emissions from all activities within the organization, including energy use, transportation, and waste.

Consistent carbon footprint reporting helps factories understand which sources emit the most greenhouse gases, allowing them to plan and set targeted goals for emission reduction. It also serves as essential data for making investment decisions in clean technologies or more efficient production processes, increasing credibility in doing business, especially when collaborating with international partners who value ESG.

In Thailand, CFO implementation is supported by the Thailand Greenhouse Gas Management Organization (TGO), which certifies companies that conduct assessments in accordance with established standards.

The Use of Clean Energy and Environmentally Friendly Technologies in the Industrial Sector

The Use of Clean Energy and Environmentally Friendly Technologies in the Industrial Sector

Shifting to clean energy, such as solar power, wind power and hydropower, in production processes can significantly reduce greenhouse gas emissions. In addition, incorporating environmentally friendly technologies, such as high-efficiency production systems, material recycling, and the use of sustainable raw materials, also helps minimize environmental impact and enhance operational sustainability in industrial factories.

Laws and Pollution Control Measures for Industrial Factories in Thailand

Thailand has enacted various laws and measures to control greenhouse gas and pollutant emissions from industrial factories. For example, the Factory Act B.E. 2535 requires factories to comply with waste and pollution emission standards. Additionally, there are measures to promote the use of renewable energy and enhance energy efficiency in the industrial sector to support the reduction of greenhouse gas emissions.

Management Approaches and Mitigation of Industrial Impact on Global Warming

Managing and mitigating the impact of industrial factories on global warming can be achieved by implementing several measures, such as improving the efficiency of production processes, using sustainable raw materials, adopting energy management systems, and promoting research and development of environmentally friendly technologies. Moreover, raising awareness and encouraging participation from the public and business sectors are essential in building long-term sustainability.

• Improving Energy Efficiency

Using high-efficiency technologies and effective energy management can reduce energy consumption and greenhouse gas emissions.

• Using Renewable Energy

Switching to energy from sustainable sources, such as solar and wind power, can reduce dependence on fossil fuels.

• Efficient Waste Management

Recycling and proper waste disposal help reduce methane and other greenhouse gas emissions.

Conclusion

Industrial factories play a significant role in greenhouse gas emissions and contribute to global warming. Recognizing the impacts and implementing measures to reduce pollution is essential for building a sustainable future. Utilizing clean energy, adopting environmentally friendly technologies and complying with laws and pollution control measures will enable the industrial sector to operate sustainably and reduce environmental impact.

References:

• 5 Ways to Solve Industrial Pollution Problems — Health & Envitech

• “Greenhouse Gases” as a Cause of “Global Warming” — Secretariat of the Senate